Handheld scanners equipped with the right logistics apps are standard tools in the world of SAP logistics. In this guide, you’ll discover how to successfully implement a mobile data entry (MDE) project within your SAP environment. We'll cover many key aspects in a compact format and provide links to more in-depth articles for those who want to dive deeper.

Ready to Make Your MDE Project a Success?

Mobile Data Entry in Logistics: An Overview

Real-time transactions, transparent inventory, and error-free processes—it’s no wonder working with handheld scanners in the warehouse and on the production line has become common practice for so many companies. When it comes to mobile data entry projects (or MDE projects), there are several important things to know, whether you're launching for the first time or modernizing an existing system.

There are many different approaches to digitalization in SAP logistics, from scanner-based work with industrial handhelds and mobile SAP transactions to advanced warehouse solutions using NFC and RFID, all the way to Pick-by-Voice or fully automated warehouses with highly complex management systems. But they all have one thing in common: digital warehouse processes are vastly superior to paper-based ones.

Our focus here is on classic MDE solutions used by countless companies running SAP as their ERP system. For these businesses, introducing mobile data entry for SAP-managed processes is a relatively simple and highly efficient way to optimize warehouse and production logistics.

Just a Few Advantages of Going Mobile

- Fast Rollout: Depending on project complexity, you can implement an MDE solution in just 2 to 6 months.

- Low Costs: Standard MDE software with ready-to-use process templates requires very little customization.

- Leverage Standard SAP Processes: Mobile scanner solutions allow you to use your existing function modules and transactions.

- Intuitive and User-Friendly: Your team won't need special training on the classic SAP GUI. After a brief introduction, they'll be ready to get to work with a handheld scanner in the warehouse.

We'll walk you through the essential topics for any MDE project in an SAP environment, covering everything from choosing the right scanner software and understanding SAP technologies for mobile data to exploring specific use cases for different SAP modules. We'll also touch on special requirements, device management, project planning, and implementation.

List of Contents

(1).webp)

1. Still Using Paper, or Are You Already Scanning?

Mobile data entry is a cornerstone of modern, digital logistics. In the SAP world especially, handheld scanners and MDE software are as much a part of the daily toolkit as forklifts and picking carts.

In practice, we see two main starting points for MDE projects in SAP logistics:

- Launching a Scanner Solution for the First Time

Is your company still running on paper? Then your main focus will be finding the right approach for your first scanner solution. - Modernizing an Existing Scanner Solution

Does your company already use a mobile solution for intralogistics? In that case, the goal is usually to update the system for modern hardware, improve the user-friendliness of the software, or add new features.

See the benefits of switching to digital picking in this case study from a long-established Swiss hospital. You can also explore the story of a global manufacturing company that successfully implemented a complete mobile solution from scratch. And if you want to learn about a successful modernization project in shipping logistics, check out this example from an Austrian beverage wholesaler.

Checklist

Check with these 10 points whether your mobile apps already have excellent UX.

2. Finding the Right Software for Your Mobile SAP Processes

How Does a Mobile Logistics App Work?

Mobile data entry works on a simple principle. SAP is, and almost always remains, the primary system where all your central data is stored and transactions happen. When you use an intralogistics app, you're essentially remote-controlling your SAP system. The app itself usually has very limited application logic.

The core idea is to capture data directly where the work happens and post it instantly to SAP. Instead of using the classic SAP GUI, data is entered on a mobile device—like a handheld scanner or a forklift terminal—through optimized mobile screens. This approach lets you use standard transactions like MIGO on the go and call up standard function modules (BAPIs) or custom Z-modules. All your master data, process logic, user rights, and business rules stay right where they belong: in your SAP system.

Mobile App as a "Remote Control" for Your SAP

What Should Mobile Software Be Able to Do?

Modern MDE software needs to support all current standard data capture technologies. Barcode scanning is a fundamental capability. Support for RFID and/or NFC-based processes is also becoming increasingly important. We're also seeing more camera-based functions integrated into logistics, from photo documentation for incoming goods to text recognition for reading order numbers on delivery slips. The right technology for your scanner solution always depends on the specific use case and your desired workflows. Ultimately, the mobile device and software are tools that should empower your employees in the warehouse or on the production line to work simply, intuitively, and safely.

Your Processes: SAP Standard or Custom and Flexible?

Several factors come into play when selecting mobile scanner software. It's crucial to look at your processes from two angles: how they exist in your SAP system, and how they are actually carried out on the floor. MDE projects generally fall on a spectrum between "close to standard" and "fully customized." Where your project lands on this spectrum can influence your choice of software. In any case, it’s always worth comparing the different solutions available to you.

Alongside SAP-centric approaches, specialized third-party providers offer tailored and flexible solutions. Sometimes, SAP's native tools can meet your mobile processing needs. However, if you want more flexibility in how you bring your vision for mobile SAP work to life, a specialized solution is often the better choice.

We also highly recommend involving all relevant departments from the very beginning of the selection process—this includes logistics and its sub-departments, production, IT, SAP Application Management, and quality management. This helps you understand and balance everyone's interests early on.

Live in 90 days

Optimize your warehouse effortlessly and cost-effectively with the Ontego subscription model.

For the Logistics and Production Teams

For departments like logistics and production, what matters most are the actual, real-world processes and how effectively the mobile solution can support them. From a practical standpoint, the project isn't just about SAP functions; it's also about crucial factors like the physical layout of the warehouse and shop floor, and existing technical systems such as lifts, scales, or other machinery. Depending on the business, you'll also need to decide if you are only mobilizing SAP processes or if you need to integrate third-party systems or accommodate unique requirements, such as an emergency mode.

For IT and SAP Application Managers

When it comes to software decisions, your IT and SAP managers will naturally have a say. This is where you'll often navigate the balance between an "SAP-first" strategy and choosing a "best-in-class" solution for a specific need—in this case, for mobile shop floor or warehouse processes. For example, imagine an IT department is heavily invested in SAP and has its own team of ABAP developers. They will likely lean towards a solution that leverages their existing resources. A flexible third-party solution with deep SAP integration, even if considered "close to standard" from an IT perspective, probably won't make the shortlist.

...But Has Anyone Thought About the Employees?

Naturally, when it comes to SAP warehouse solutions, the focus is often purely on data entry with a mobile device. But someone has to use those devices and MDE apps. Every single day. Eight hours a shift. That someone is your team in the warehouse, on the production line, and in shipping. A streamlined, user-focused mobile experience is a critical success factor for any MDE project and its long-term effectiveness. Our experience shows that modern, user-friendly software for mobile data entry is absolutely possible, even in the SAP world.

When planning your mobile SAP application, be sure to consider these five points:

- Design interfaces specifically for rugged devices.

- Enable operation via both touch screen and physical keyboard.

- Fully integrate handheld functions and peripheral hardware.

- Account for the different form factors of your devices.

- Develop once, and reuse everywhere.

.jpg)

3. Offline vs. Interruption: Does It Matter?

Yes, it absolutely does. It's a question that comes up in nearly every project, usually from the logistics or production managers. In the real world—whether you're in a warehouse or out in the yard—smooth, uninterrupted work is essential. Technically, we distinguish between brief connection interruptions that an MDE app needs to handle gracefully, and true offline scenarios where your team needs to work for an entire shift without a data connection.

Buffering for Brief Disconnects...

When you use an MDE solution for SAP production or intralogistics, your mobile devices typically communicate with the SAP system over a Wireless LAN (WLAN) connection. As long as that connection is stable, data flows freely between SAP and the scanner app. But what happens when the internet goes down, like at an overseas plant, cutting off the connection to your central SAP system?

Think about a typical warehouse with its metal racking; it's perfectly normal for Wi-Fi signals not to reach every single corner. Even in a fully Wi-Fi-covered area, you can expect brief connection drops. The primary cause is the constant movement of the mobile devices. Even with optimal wireless coverage, moving outside the covered area can't be completely ruled out. Additionally, interference can also lead to connection fluctuations.

However, this usually doesn't have a noticeable impact on the work, as long as the software on the handheld devices can handle connection interruptions. We call the ability to manage these Wi-Fi drops "interruption handling." So, what does that mean?

First, it ensures that the user's current session isn't lost during a brief offline moment. Second, it allows data to be captured on the device even if the connection is unavailable for a while, holding it until it can be sent to the backend system. Data can be sent later or re-sent. Ideally, the employee doesn't even notice the connection was briefly lost and can continue working smoothly. Only when it's time to post a transaction would they need to move to an area with coverage to send the data to SAP.

...vs. Working Continuously Without a Data Connection

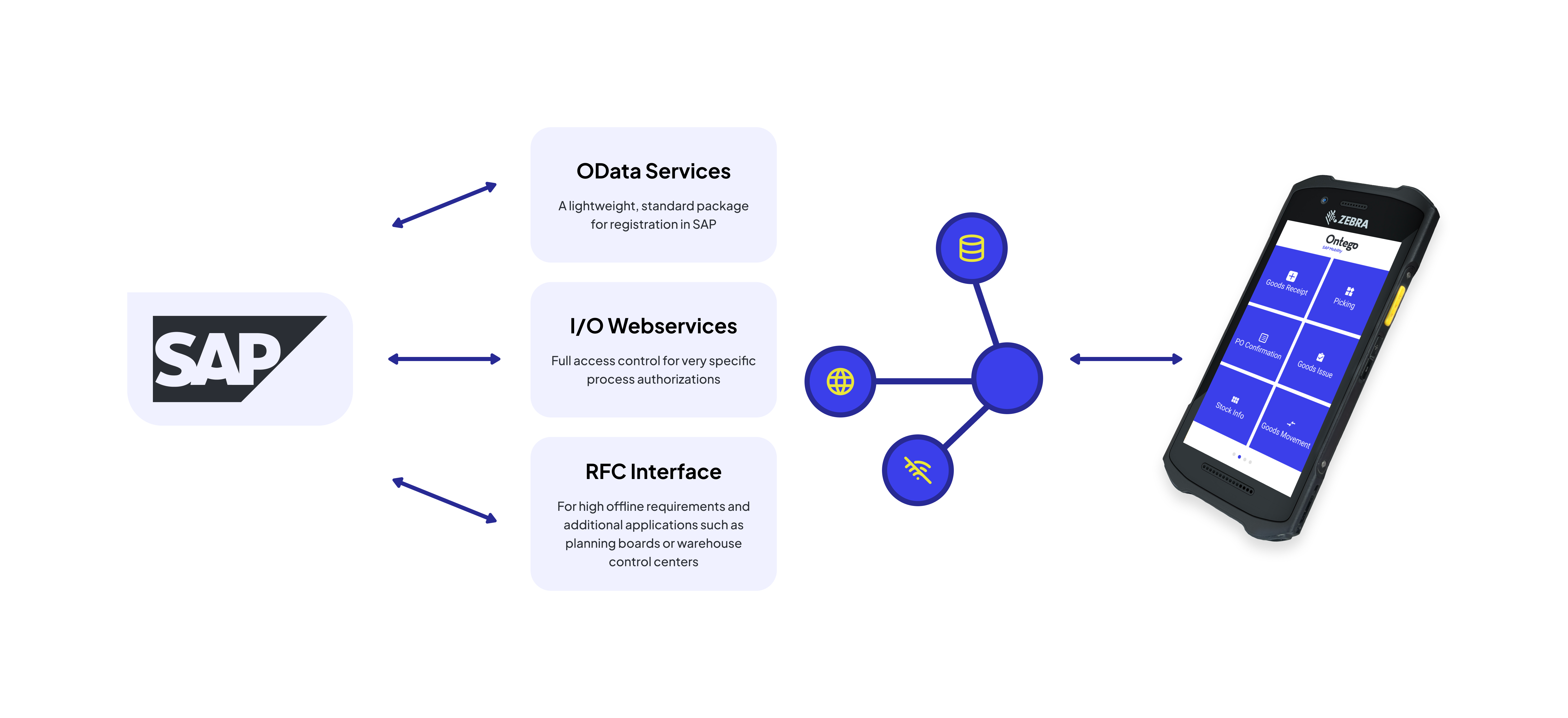

True offline-capable scanner solutions are also possible. By "true," we mean the ability to work with a handheld device for an extended period without any connection to the SAP system. This requires a synchronization mechanism and a middleware component—an intermediary server. This server enables either one-step or two-step data synchronization. One step is responsible for syncing data between the SAP system and the server, and the second step syncs data between the server and the app.

One- or two-step synchronization via middleware

SAP Leads on Master Data

The one or two-step synchronization mechanism used in the MDE solution relies on regular data comparisons and checksums to ensure data is transferred correctly at all times. As a rule, SAP will always remain the leading system for managing master data and inventory levels.

Mobile Software Leads on Transactional Data

For data that is read from SAP and intended to be modified in the app, the server component takes the lead in an offline solution (enabling write access to SAP). It's also crucial to have a conflict management system in place for these scenarios. This system can resolve issues that arise when conflicting data changes are made simultaneously in SAP and in the warehouse app.

Logging and Monitoring

The server component logs all goods movements and transaction processes. Using a monitoring application with defined filters, you can, for example, view and correct any erroneous SAP postings. This helps to significantly minimize manual effort.

4. Which MDE Approach Is Right for Your Project?

In the SAP ecosystem, there are several paths to enabling mobile work. You have SAP's native technologies that focus on its own ecosystem, specialized third-party solutions that offer greater flexibility and connectivity to other systems, and even platforms that let you build your own mobile applications, if you have the desire and resources.

What About Fiori for SAP Warehouse Logistics?

SAP offers its own native UI technologies for accessing its various modules. Unlike the classic SAP GUI designed for desktop use, SAP Fiori provides a modern framework that can, in principle, be used for app-based solutions.

However, Fiori applications are not optimized for mobile use in production logistics or warehouse environments. Real-world examples—and even reports from SAP-affiliated consulting firms—highlight several weaknesses:

- There is no standard Fiori application for warehouse processes, and SAP has no plans to develop one for Warehouse Management or Stockroom Management.

- From a technical standpoint, Fiori apps tend to transfer large amounts of data, which leads to poor performance on mobile networks.

- The mobile user experience is often hampered by frustrating UI behaviors, like the on-screen keyboard popping up at inconvenient moments in a workflow.

Our takeaway from countless conversations is this: it's nearly impossible for a company to cover its warehouse processes using standard Fiori apps. On the other hand, building custom Fiori apps requires a significant development effort, which means you need the right internal or external resources.

"When faced with more complex or custom needs, companies find that standard Fiori apps quickly hit a wall."

The RF Framework: SAP's Somewhat Rigid Standard

Within its Extended Warehouse Management, SAP offers another technology for mobile data entry: the Radio Frequency (RF) Framework. The RF Framework provides a highly standardized structure that covers all key intralogistics processes but leaves very little room for custom process variations.

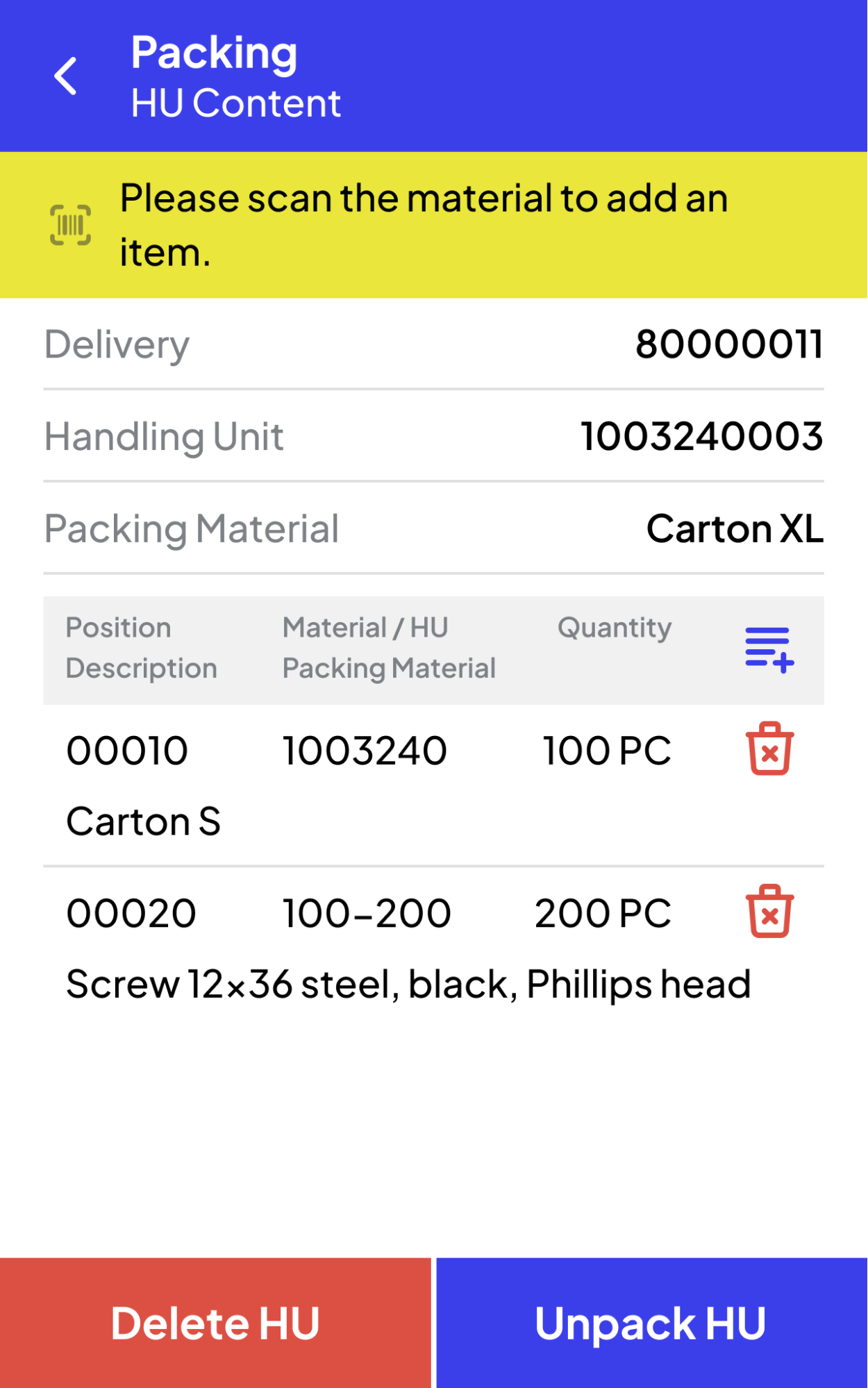

Flexibility Through Specialized Software for Logistics Apps

This is where specialized software solutions come in. They provide high-performance logistics apps with intuitive layouts tailored to your employees in the warehouse and on the production line. Integration with SAP is handled via standard interfaces like web-service-enabled function modules, OData services, or the classic Remote Function Call (RFC).

Some of these specialized MDE platforms also give you the option to develop logistics apps on your own. This "self-development" can range from simple tweaks to building complex applications from the ground up. With this approach, it's clear that you'll need to allocate internal resources. And an often underestimated, but critical point: the best tool is only effective if you have the know-how to develop mobile applications.

This innovative engineering company shows that with the right training, it's entirely possible for businesses to create their own applications.

Regardless of the technology you prefer, success ultimately comes down to well-designed processes and their technical implementation on mobile. The result is an MDE solution—sometimes a browser-based application, sometimes a modern scanner app—that enables mobile work in your warehouses and on your shop floors. The following sections show examples of mobile processes for typical SAP modules.

5. Documenting Material Flows on the Go (SAP MM)

SAP Material Management (SAP MM/IM) is all about efficiently managing and controlling the flow of materials through your business. But you only unlock its true potential when transactions are posted instantly, right where the action happens, using a handheld scanner—not delayed and entered later at a desktop terminal. This approach eliminates the backlog of paperwork in the warehouse office and creates genuine, real-time transparency.

Mobile MM Transactions

Theoretically, any standard SAP process can be mobilized.

- Achieve full transparency: By posting transactions in real-time, your entire material flow—from goods receipt and internal movements to physical goods issue—is reflected accurately in SAP.

- Keep inventory accurate: When you handle transfers and inventory counts directly on a mobile device, your SAP stock levels stay much closer to the physical reality in the warehouse than is possible with delayed data entry.

- Go beyond the basics: You can also call up and process any other SAP transaction on the go, such as making master data changes or creating purchase requisitions.

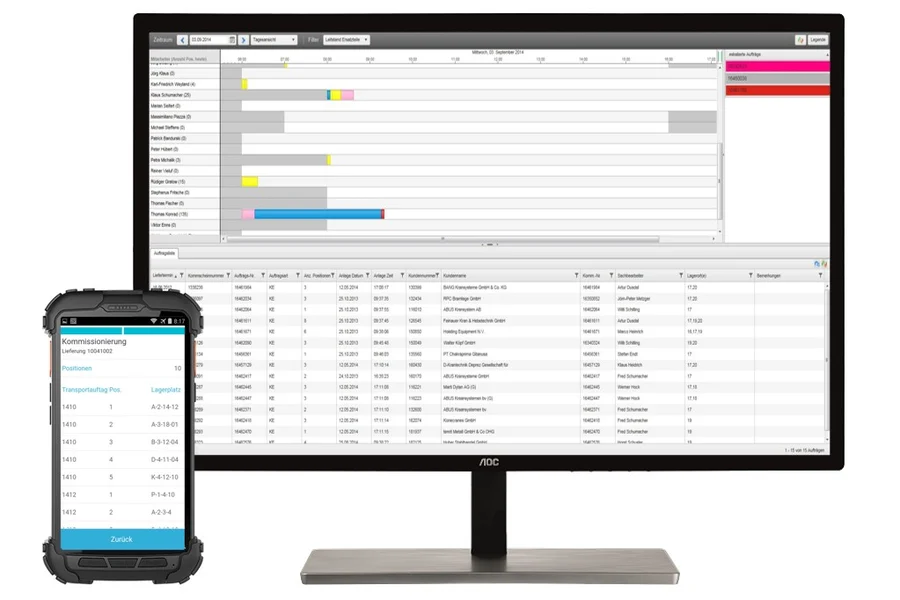

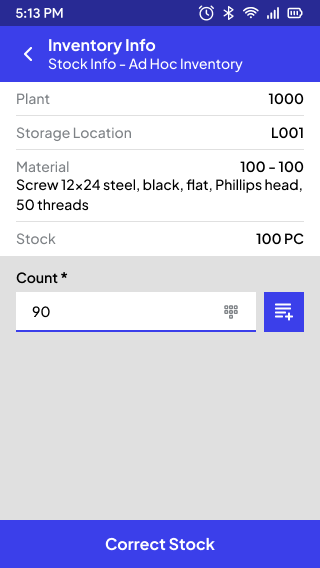

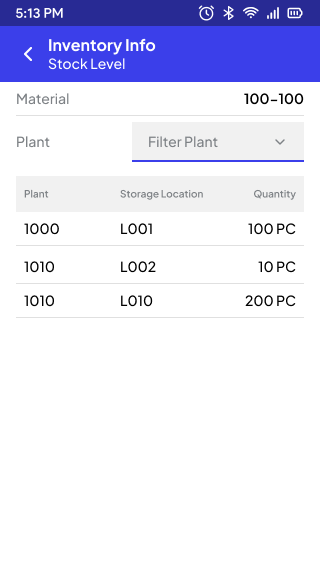

A Practical Example: A mobile inventory query at the material level can be this simple—the scanner app pulls the data directly from the SAP material master. Here’s the clever part: the material information query is linked with an ad-hoc count of that material's quantity:

Fig. 1 MM Inventory Information Scan Material

6. Keep an Eye on TAs, Queues, and Bins with Mobile (SAP WM)

For mapping and controlling more complex warehouse structures and processes, SAP offers the Warehouse Management (WM) module. SAP has announced that support for SAP WM will end in 2027. As SAP encourages a gradual migration to SAP S/4HANA, it offers its WM customers a transitional alternative under S/4HANA called Stockroom Management, which is a version of LE-WM with limited functionality.

Naturally, the extensive warehouse management and control capabilities of SAP WM can also be handled on mobile devices.

- Putaway, transfer, or picking strategies based on transfer orders can be easily processed by your warehouse staff using mobile handhelds.

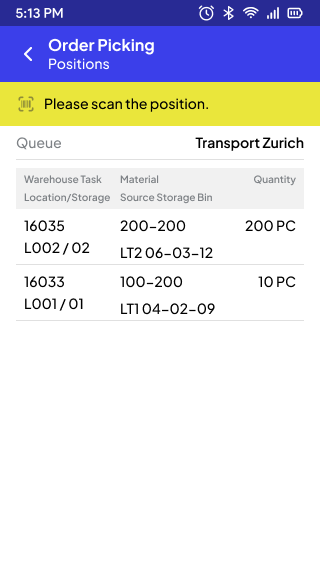

- Workloads are distributed to employee's mobile devices via queues. This ensures transfer orders are processed in a structured way, and individual steps can be validated with a simple barcode scan.

- In mobile picking, warehouse apps speed up the processing of picking orders and help to reduce error rates.

- The mobile software also allows you to intelligently link processes together. For example, during a material removal, a warehouse employee can perform a zero check or a remaining quantity check, with the corresponding control quantity reported back to SAP. This allows you to integrate a continuous cycle counting process directly into your workflow.

- Furthermore, SAP WM supports modern technologies like RFID. Mobile work with handhelds and barcode scanning can naturally be integrated into these more complex process flows, for instance, by triggering the printing of RFID labels from a mobile device or by reading data from RFID tags to automatically populate fields in the mobile software.

The specific optimization effects that can be achieved with mobile picking during day-to-day operations are clearly demonstrated in the example of this premium Swiss wine distributor.

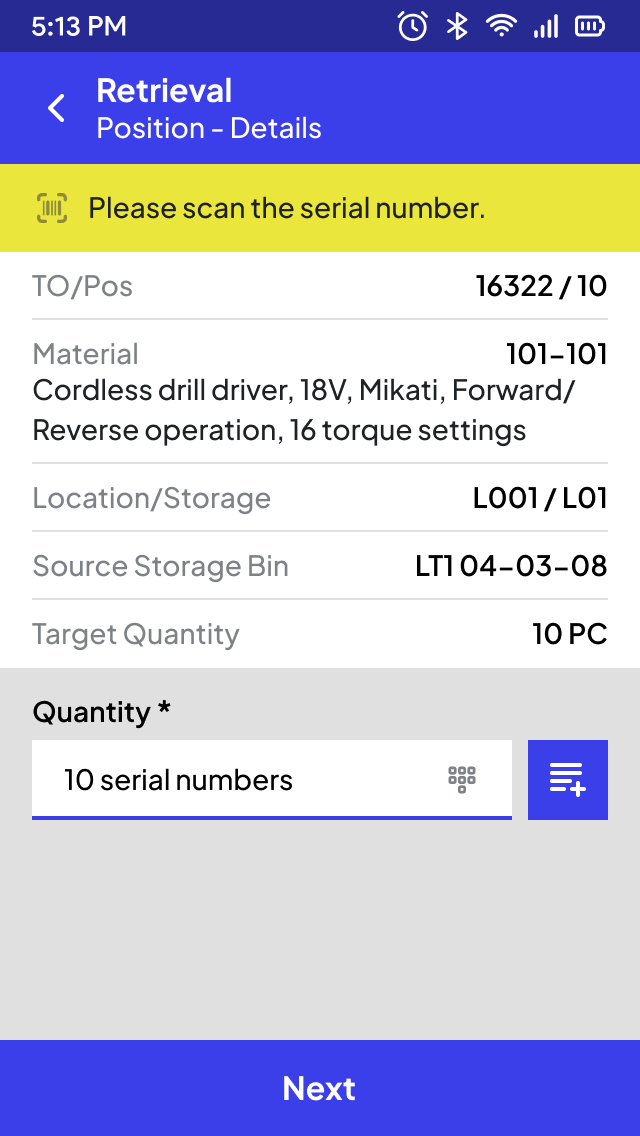

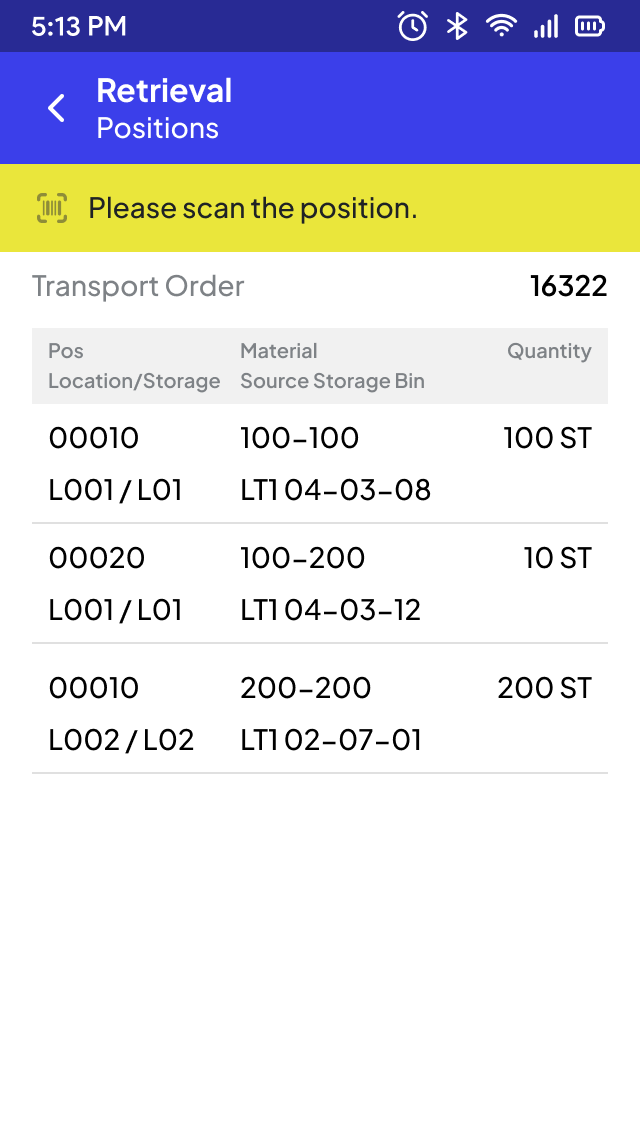

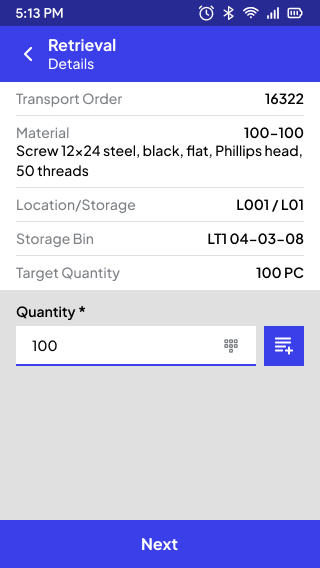

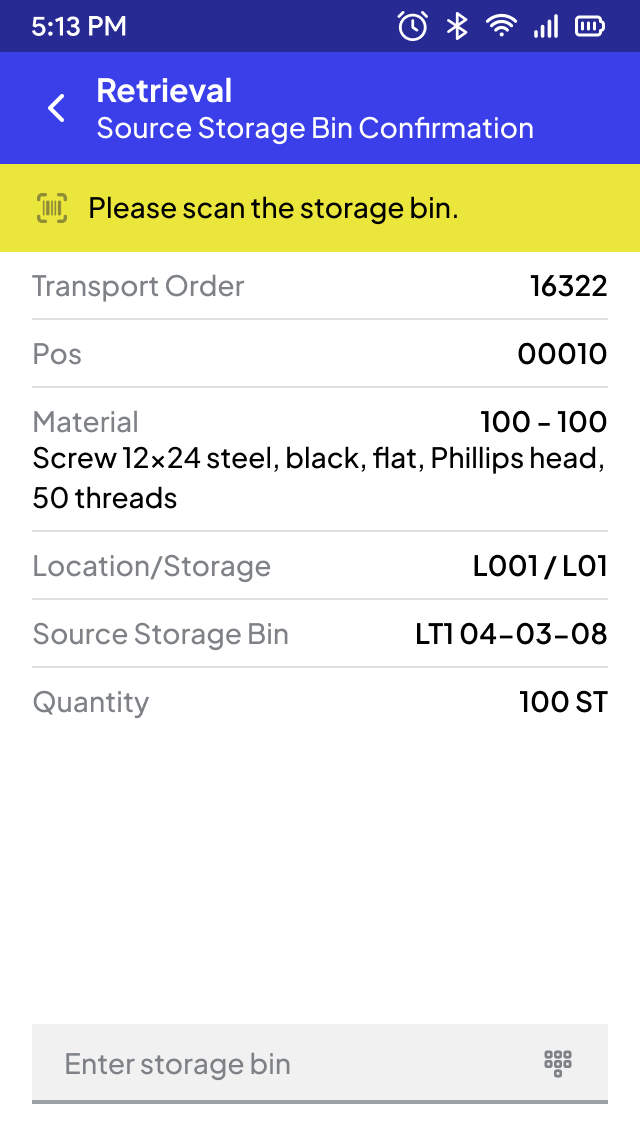

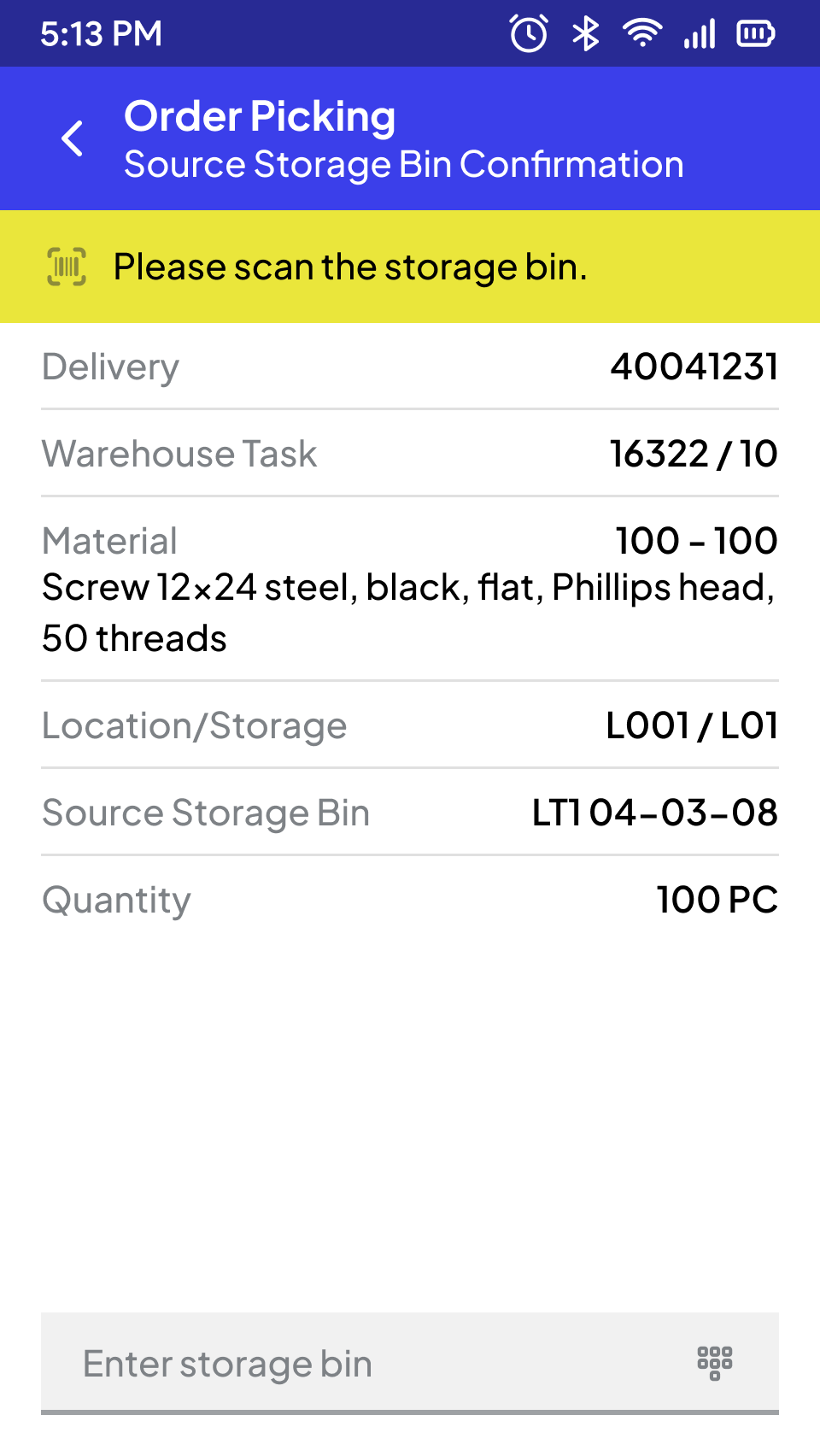

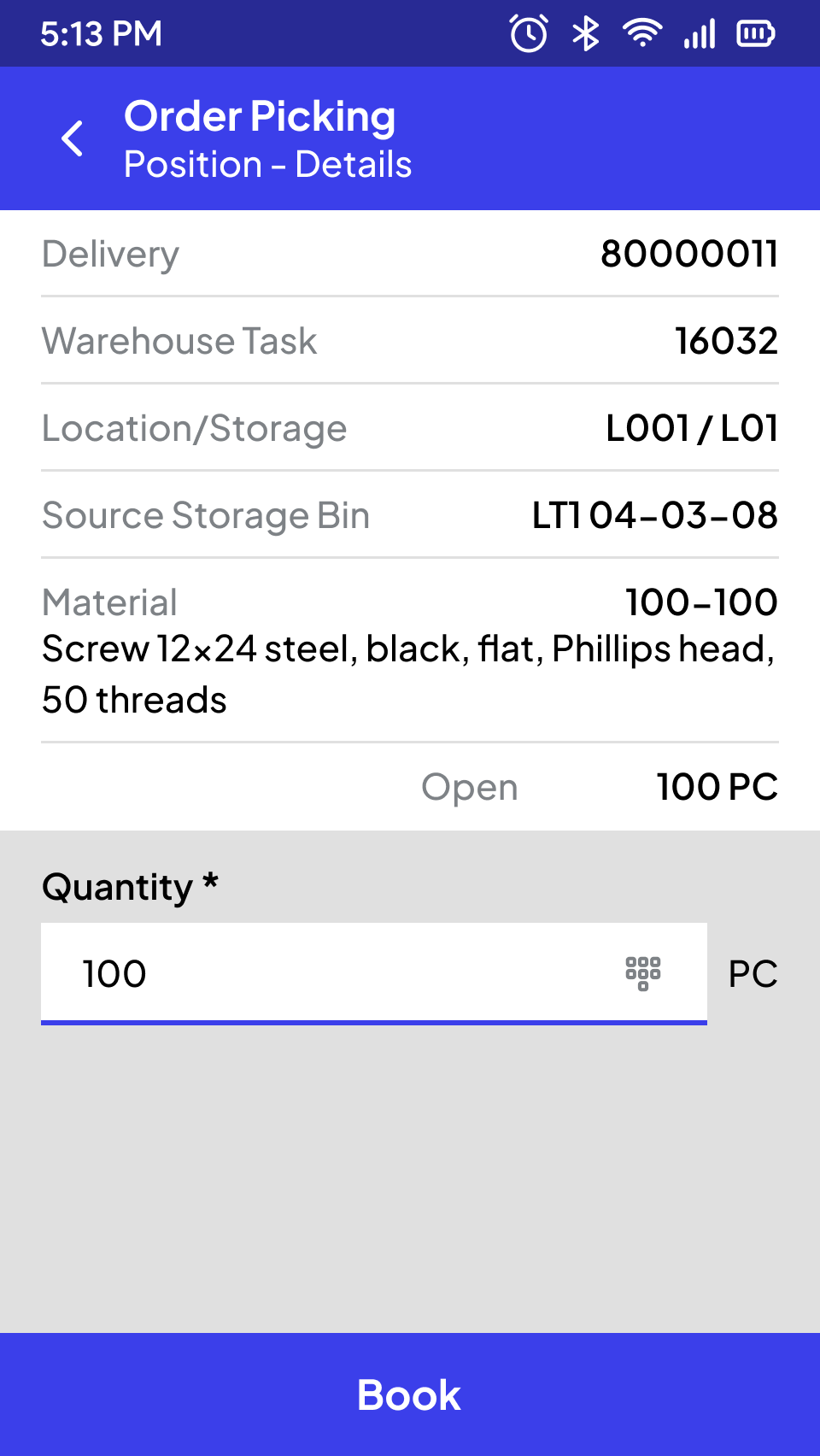

A Practical Example: Removing materials based on SAP transfer orders is a classic example of material movement in an SAP-managed warehouse. The process can be started by selecting a specific transfer order (TO) or via an SAP queue—with the option to integrate specifics like handling units or serial number tracking.

Fig. 1 WM Transfer Order: Entry into stock removal via transfer order number

7. Handling Warehouse Tasks via Handheld (SAP EWM)

Companies implement complex and automated warehouse processes using SAP Extended Warehouse Management (EWM). On the market since 2005, EWM is positioned by SAP as the successor to SAP WM and the preferred warehouse management system under S/4HANA. With its comprehensive capabilities for warehouse process control, EWM naturally includes provisions for mobile data entry. This can be implemented using the integrated, highly standardized Radio Frequency Framework (RF Framework) or with flexible third-party systems.

Finding the Optimal Mobile Solution for EWM

A crucial question for EWM users is always which technology is the right fit for mobile work. SAP's RF Framework takes a pragmatic, functional-first approach. While it lets you process tasks on a mobile device, it often neglects modern user experience and flexible process design.

"The user interface on the RF Framework via ITSmobile is cramped with tiny fonts and data fields that are too small for practical use."

As an alternative to the RF Framework, you can use native app solutions for your SAP EWM-based logistics processes that communicate directly with SAP and EWM. These apps can be based on standard RF transactions or tailored from the ground up to your company's unique workflows. A special case where a custom solution might be used is when mobilizing EWM processes together with processes from other SAP modules—for example, in an MM-managed warehouse within a single, integrated scanner solution.

This last point about customization is especially crucial in practice on the shop floor or in the warehouse. The efficiency of your EWM-driven processes should be reflected in your MDE solution. This means having input sequences and user interfaces that are designed around the user and laser-focused on the task at hand.

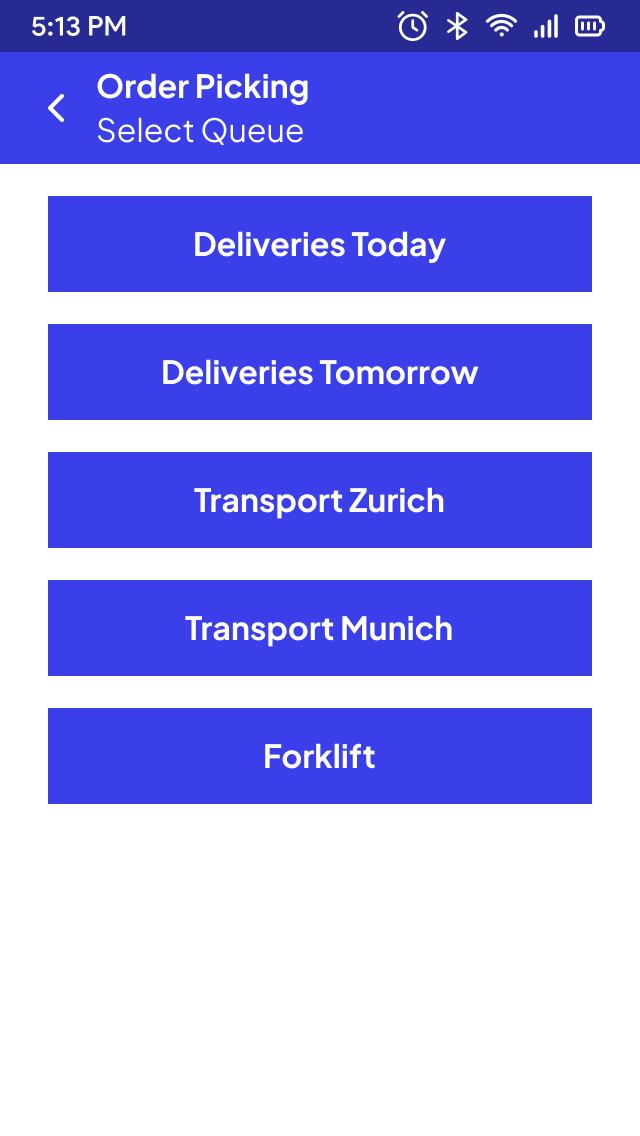

A Practical Example: In an EWM-managed warehouse, efficient picking is handled via queue management. In addition to letting users freely select from available queues, you can also make targeted assignments to specific employee groups.

Fig. 1 EWM Picking: Selection of a queue and entry into picking

8. The Shop Floor Goes Mobile (SAP PP)

In a production environment, mobile data entry delivers gains in speed, transparency, and data accuracy. It makes sense, therefore, to mobilize processes controlled by SAP Production Planning & Control (SAP PP) right where the work happens, adding value through direct posting of confirmations, times, or similar data.

Using mobile devices to manage transports to our production supply areas has significantly improved how accurately we get the right materials to the assembly line.

Mobile Confirmations for Production Orders

The flow of materials to the production line—sometimes via an interim production supply area (PSA)—is one of a company's most critical processes. This makes it all the more important that production is supplied with the right materials, in the right quantity, at the right time—and that it's all booked in real-time. An SAP-integrated mobile application that allows employees in logistics or production to document their activities directly can noticeably boost process reliability. Furthermore, mobile production confirmations, especially when combined with time tracking, improve data availability and simplify subsequent processes and analyses, such as calculating performance-based wages.

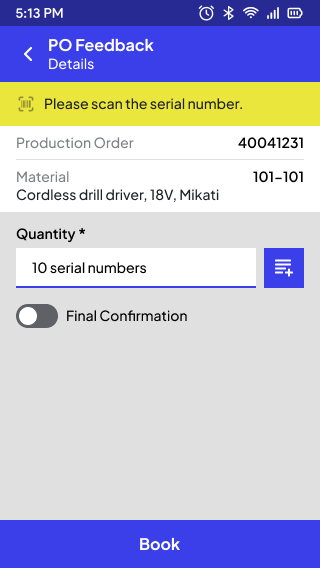

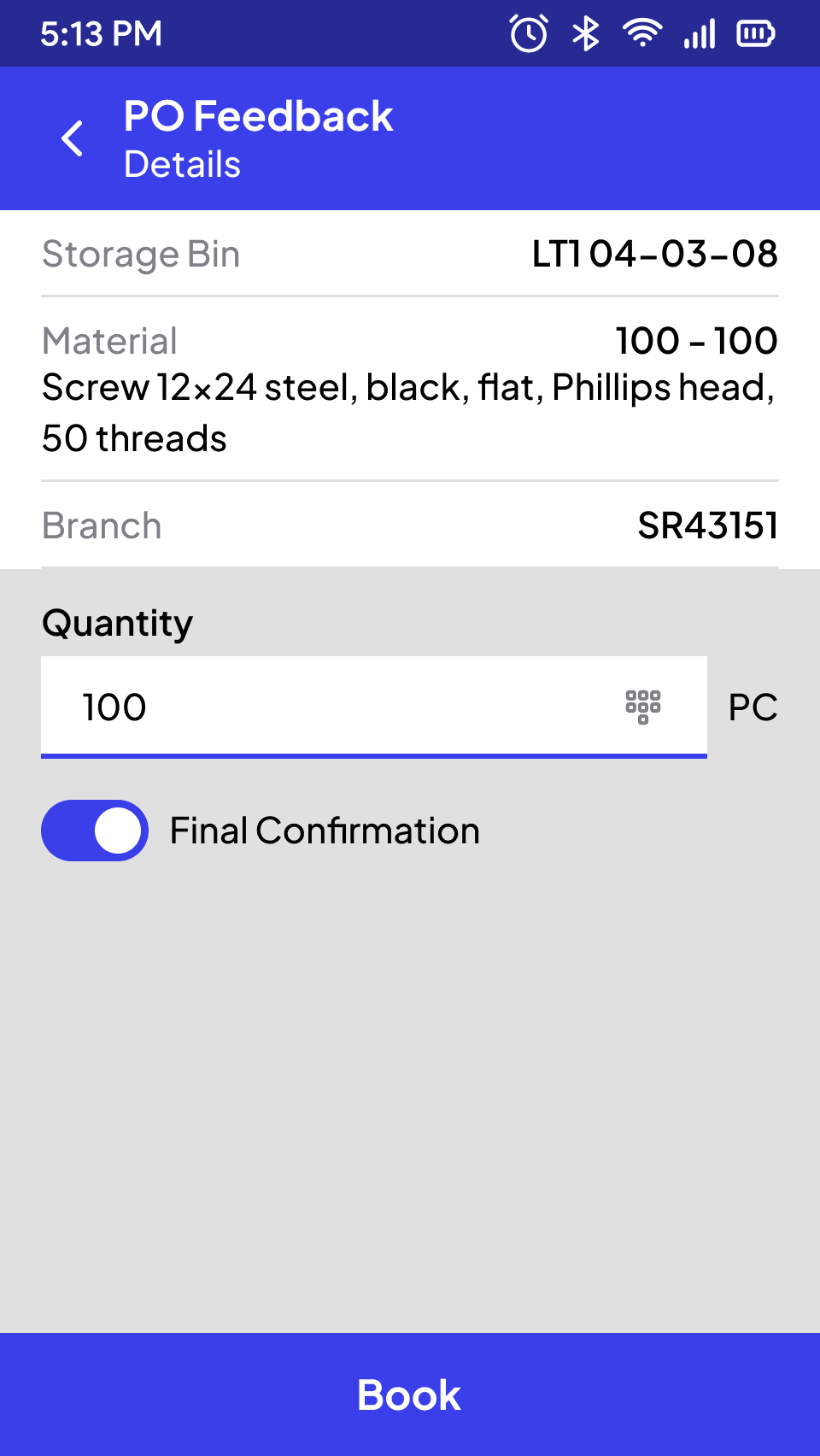

A Practical Example: Timely feedback from the production line is essential for triggering downstream processes, such as initiating a quality inspection or moving on to further processing steps.

Fig. 1 SAP PP Production Confirmation: Entry via scan of a production order

Mobile Kanban

Replenishment control, especially for supplying production lines, can be optimized with mobile SAP processes for Kanban containers. In addition to checking the status of one or more Kanban containers, you can implement various methods for changing their status. For example, a status change can be initiated by capturing the container ID via barcode scan, OCR, or manual entry; the target status can then be set automatically or manually. If the status change results in an open Transfer Order (TO) item in WM or a warehouse task in EWM, it can be automatically confirmed by the mobile software.

Poka Yoke and Mobile Data Entry

The automotive industry is known for its highly detailed and strict process and quality requirements. Poka Yoke, or "mistake-proofing," in production stands for rigorous quality standards. It allows suppliers to transparently meet the requirements of auto manufacturers. This principle can be seamlessly integrated into mobile data entry with SAP. By enforcing strict scanning protocols, production processes are effectively mistake-proofed, and each manufacturing step is transparently documented in SAP.

Mobile Time Tracking in Production

Manufacturing companies often motivate their employees with performance-based wages or bonuses. The foundation for this type of payroll in SAP is the precise recording of employee-specific production times. This mobile time tracking can be integrated directly into a mobile data entry software solution. This allows you to create comprehensive mobile solutions that don't just solve isolated needs but can offer specific functions based on employee roles and individual permissions.

The synergy effects that can be achieved by linking mobile time tracking with other functions, such as mobile confirmations for production orders, are demonstrated in this example from an innovative office furniture manufacturer.

9. Get Shipping Right (SAP SD)

In the context of SAP Sales & Distribution (SD), mobile data entry is crucial for posting physical goods issues from the warehouse, as well as for packing and the actual shipping process. In most cases, the primary focus is on preventing incorrect deliveries. Or, to put it another way: securing the shipping process through validation checks and goods issue controls.

Posting Packing Processes on a Handheld

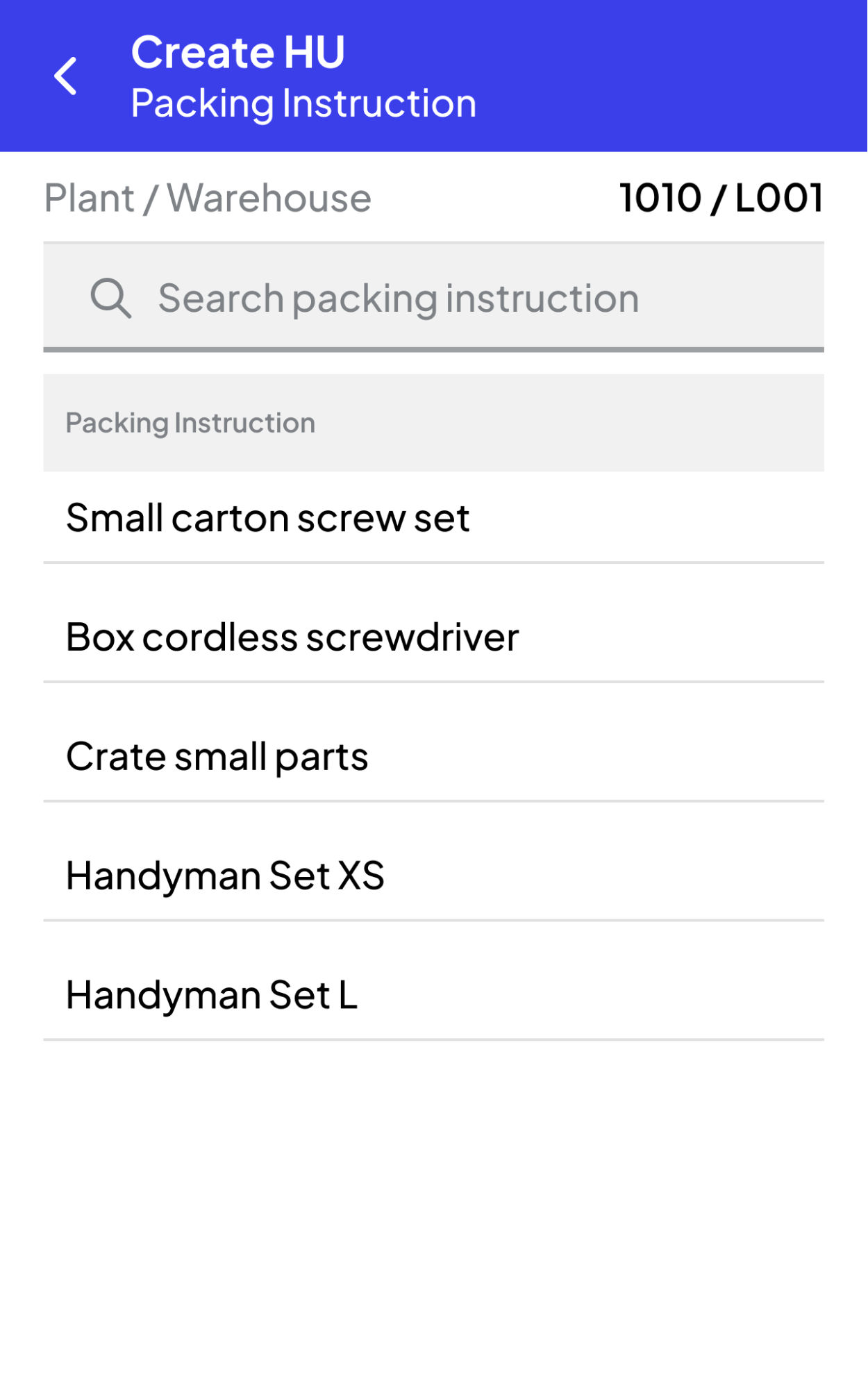

Mobile processes for packing can cover everything from managing independent Handling Units (HUs) to handling HUs related to a specific delivery or shipment. Your mobile software can adopt packing proposals and complete packing instructions created in SAP. Additionally, you can take photos of HUs for documentation and save them to a designated location.

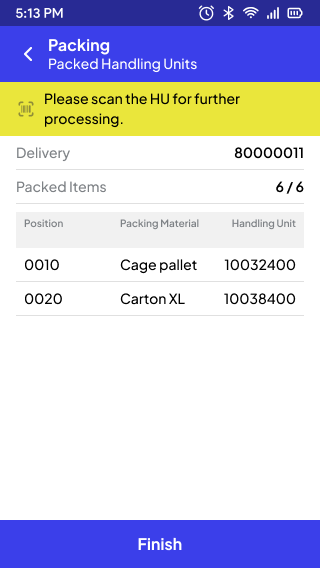

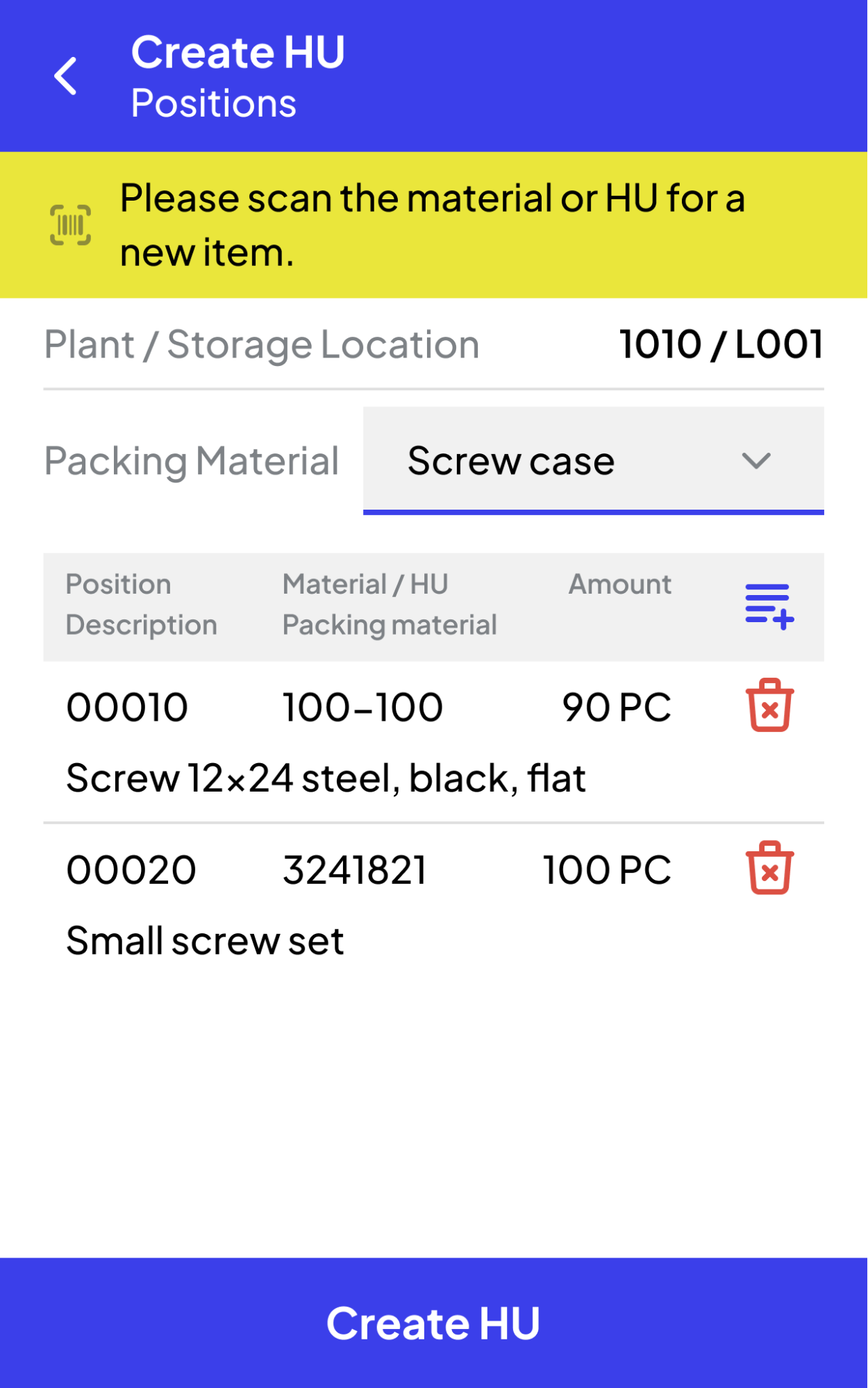

A Practical Example: Below, you can see different variations of packing processes—from the free creation of a Handling Unit with or without packing instructions, all the way to an SAP-guided automatic packing procedure.

Fig. 1 SAP SD Packaging Process: Items with packaging material proposal

Mobile Shipping Control

The loading processes include a goods issue control check on an MDE device. Depending on how your SAP system is set up, a warehouse employee can perform these mobile shipping checks using a specific delivery number, a shipping element or material item, Handling Units, or a transport number.

If the shipping process requires a control check, loading can only proceed after confirmation on the MDE device. The corresponding posting of the loading or transport status is done in SAP directly from the loading point. Here's an interesting feature: the mobile software can handle the status changes in SAP in the background based on defined algorithms. This frees up your warehouse employees to focus on their physical tasks and control scans.

When implementing goods issue controls, you can also cater to specific requirements, such as using cross-scans of the HU label and the truck ramp label to ensure a pallet is loaded onto the correct truck.

10. Beyond SAP: Add-ons for MDE Processes

So far in this guide, we've mostly talked about scanner solutions within the scope of standard SAP processes. Of course, custom Z-transactions can also be controlled via mobile, and with the right software, third-party systems like storage lifts or scales can be operated from the handheld device.

.jpg)

MDE Integration for Storage Lifts

Sometimes, unique process variations require custom MDE solutions that aren't available in the SAP standard. Let's imagine you need to put away small parts in a storage lift. Traditionally, a warehouse employee would operate the lift manually and wait for a period until the selected storage tray becomes available.

To eliminate this waiting time, you can control the storage lift directly from the mobile software. Transfer Orders (TOs) with source and destination bins in a storage lift can be processed by the mobile software's server component and optimized so that the processing of TO items—whether picking or putting away goods—happens with reduced or even zero waiting time.

Warehouse Control Center Complements MDE Solutions

In logistics scenarios that require a higher level of coordination and monitoring, a warehouse control center can be a powerful addition to your mobile data entry solution. A classic example is using a control center for picking. With a tool like this—usually a browser-based desktop application, sometimes enhanced with a graphical planning board—dispatchers can plan picking for shipping or production, manage the workload of warehouse staff, set priorities, and systematically respond to escalations.

Authorized users can plan and manage workloads using drag and drop, for example. They can either use existing transfer orders from the SAP system or manually create orders in the control center. The employees who receive these transfer orders get them in their worklist and have the option to accept and execute them, or to reject them. When defined thresholds are reached, warning notices and escalation routines are triggered.

Mobile Data Entry in the Outdoor Warehouse

Scanning in an outdoor warehouse presents a unique set of challenges. Wi-Fi is often spotty or completely unavailable, and pallet labels can be too small to scan from a distance. Add direct sunlight to the mix, and the frustration is complete: the laser aiming dot on the MDE device is difficult or impossible to see, and glare on the screen makes work difficult. However, solutions do exist to implement efficient scanning processes even in outdoor areas of a warehouse. The following aspects play an essential role in the success of an MDE project in an outdoor yard.

- Wi-Fi or cellular connectivity

- QR codes with a minimum size

- Using handhelds with long-range scanners

- Optimizing barcode capture

- Software suitable for outdoor lighting

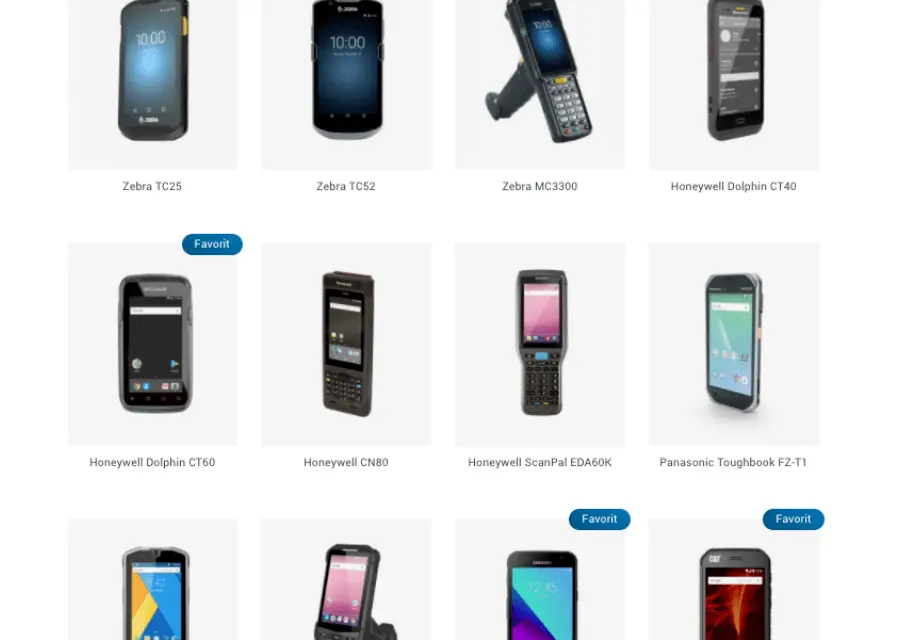

11. The Right Device for Every Job: Handhelds, Tablets, & Forklift Terminals

Mobile data entry involves more than just SAP as the leading system and the mobile software as the tool to remote-control it. Choosing the right hardware for each specific use case and, potentially, a solution for unified device management, is just as important.

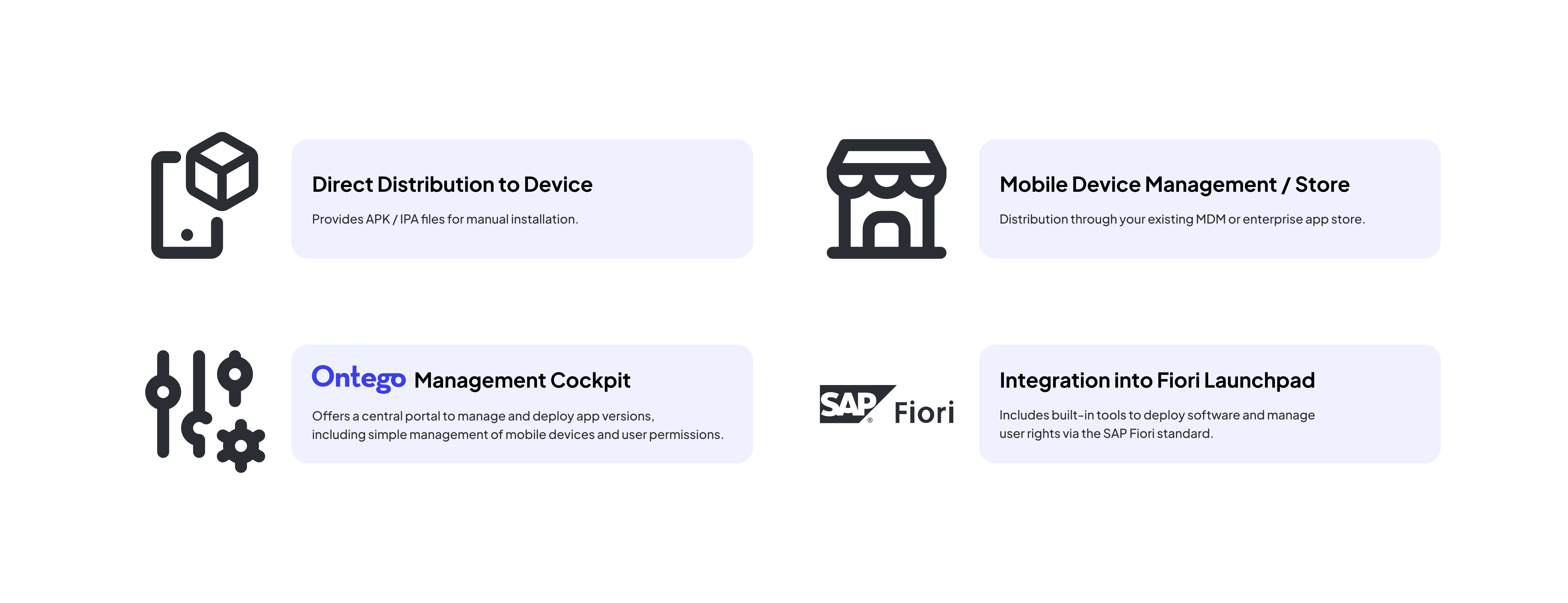

Variations of Software Distribution

Finding and Selecting Mobile Devices

The variety of rugged devices for mobile data entry in industrial environments has grown enormously in recent times. In warehouse logistics or production, forklift terminals and especially handhelds with integrated scanners are among the most frequently used device types. In less harsh environments, rugged smartphones are also sometimes used. To identify the right devices for your company, it's worth taking a close look at your mobile processes and your employees' work environment. It's also important to keep future maintenance and repair needs for your handhelds or forklift terminals in mind.

Mobile Device Management

It's a good idea to think about the administration, maintenance, and control of your mobile devices early on in a mobile project. So-called Mobile Device Management (MDM) or Enterprise Mobility Management (EMM) solutions are available for this purpose. These software solutions are an essential component for any project with a large number of mobile devices, for projects where devices are used off-site, or for global rollouts.

There are numerous providers available on the market, including well-known international providers such as Soti, Sophos, MobileIron, and VMware Workspace One. In addition, there are also various providers in the DACH region, such as Pretioso, Apptec360, and Gdata.

Free Guide

Use our Hardware Finder to choose the right mobile device.

12. Planning and Implementing Your MDE Solution

Planning and implementing an MDE solution is an investment project that requires support from various departments within your company. The key players are the managers from the requesting department (often logistics or production), the IT department, and specialists like the heads of goods receipt and shipping or the SAP application manager. Furthermore, the involvement of colleagues from related departments is often required. For instance, the purchasing department might need to be involved in a project, as well as the legal department and the data protection officer.

Here are a few brief tips for the planning and implementation of an MDE solution:

Commercial Approaches: On the market, you will find different pricing models. On one hand, there is the classic model, which includes the purchase of licenses for the software and users, plus the implementation of an introductory project. On the other hand, you can also find pricing per mobile process, as well as usage-based billing models (a subscription model) with a lower initial investment.

The reasons for choosing such a subscription model are shown by this innovative plant engineering company from the globally active Arvos Group.

Scope of Use: During the internal preparation for an MDE project, you should determine the precise extent to which the future mobile solution will be used. A list of the locations and respective user numbers is helpful for this. You should also clarify if there are any plant-specific requirements and whether the software needs to manage user permissions.

Hardware: Check if there are any special requirements in your logistics environment that need to be considered. For example: long-range scanning (for high-rack warehouses, outdoor yards), areas without Wi-Fi coverage (outdoor yards), or specifications for explosion-proof (EX) devices or disinfectant resistance.

Technical Prerequisites: Before the actual implementation, the following technical conditions should be checked and, if necessary, established:

- Access to the SAP test system

- VPN access

- Developer key for support with web service creation

- Provisioning of a server

- Procurement and setup of a Mobile Device Management system

- Involvement of an IT service provider

Project Planning: For the actual realization or customization of a scanner app, you can plan for a timeframe of 2 to 6 months, depending on the number of mobile processes. For your timeline, it's also important to remember that several preliminary project steps are necessary: internal preparation (functional specifications, budget planning, departmental coordination, etc.), vendor selection (research, quotes, negotiations, etc.), and project preparations (infrastructure, access rights, etc.).

Implementation: An example workflow for an implementation can include the following steps:

- Workshop, detailed concept, and approval.

- Implementation and testing phase, including the preparation of test data for standard and edge cases.

- Go-live date at the pilot site and a hypercare phase.

- If applicable, dates for the roll-out at additional locations.

Know-how

Speak to an expert in mobile data capture in SAP logistics.

.png)

.png)

.png)