Topics

In the pharmaceutical industry, regulatory requirements influence many processes—including intralogistics. For Luye Pharma, a specialist in the development and manufacturing of patches containing active ingredients, these requirements were the motivation to digitize its warehouse logistics processes. Thanks to a mobile SAP scanner solution, warehouse movements are now handled efficiently and transparently.

Luye Pharma, based in Miesbach, develops and produces so-called transdermal delivery systems with its 260 employees. These are medicated patches through which, for example, pain medication can be administered. Within Europe, Luye in Miesbach is the second-largest producer in this product class and, as part of the Luye Pharma Group with a total of 4,000 employees, is embedded in a growing pharmaceutical concern.

GMP & the Obligation for Accurate Documentation

The decision to introduce a mobile SAP solution was made in 2020. Several reasons played a role in this, recalls Franz Geiger, Warehouse Manager at Luye Pharma in Miesbach. "One of the main reasons was the trend towards increasing digitalization and the desire to establish more efficient and secure work processes." According to Geiger, traditional, paper-based processes are time-consuming and inherently prone to errors. The use of scanners was intended to address these problems while simultaneously increasing the mobility and flexibility of the employees.

The topic of GMP - "Good Manufacturing Practice" - is crucial for Luye. GMP stands for a code of good manufacturing practice for medicinal products. This set of rules is intended to ensure that pharmaceutical products are provided in high quality. These quality standards apply during the manufacturing, processing, and packaging, as well as the storage of medicinal products.

In addition, there are further legal regulations that must be taken into account in Miesbach: Besides classic warehouse areas like a high-rack warehouse, a small parts store, or preparation zones, Luye also manages a cold storage warehouse and a solvent warehouse. Precise documentation of all material movements is required in all warehouse areas. "It just has to be guaranteed that it's a secure process," emphasizes Geiger.

Learn everything about modern mobile SAP apps in warehouse and production.

Digital, Secure Processes in SAP Logistics

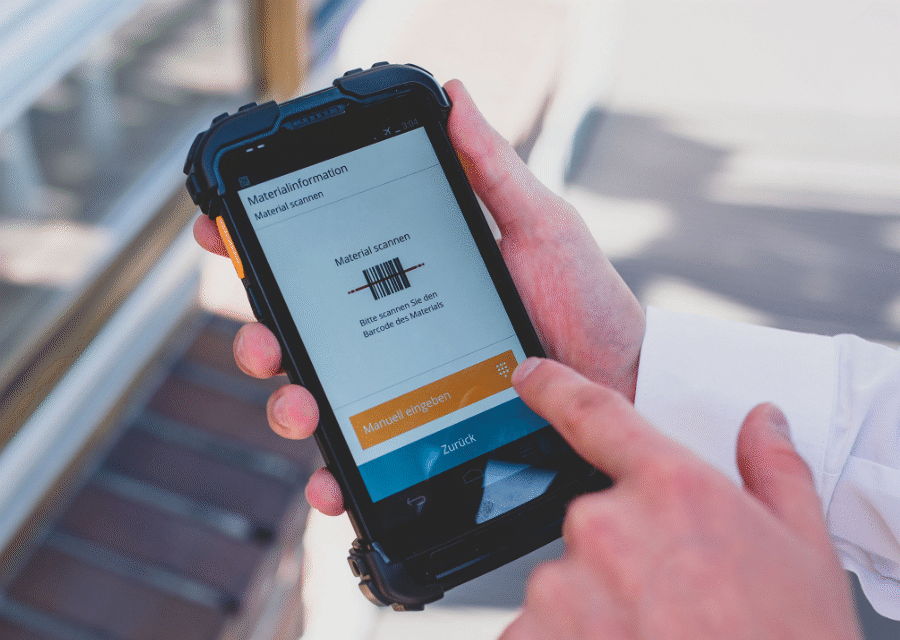

The implementation of the mobile SAP solution, based on the Ontego software, was carried out in stages at Luye Pharma. The goal was to map the entire process flow in the logistics app, from goods receipt with putaway and internal transfers, all the way to process orders and picking for delivery and goods issue.

The following SAP warehouse processes are documented on mobile devices at Luye:

- Goods Receipt

- Putaway

- Internal Transfers

- Goods Issue with picking, checking and confirmation of the goods, and the GI posting

Additionally, labels can be reprinted via the mobile device.

For Franz Geiger, the advantages of mobile data entry are clear to see: "The scanner solution has proven itself, especially in goods receipt and for internal transfers, as it has significantly simplified and accelerated our workflows." The mobile SAP logistics app enables seamless tracking and documentation of these processes, which not only increases security but also fulfills the requirements for audits and inspections.

MDE Helps with Audits and Inspections

An interesting side aspect—especially for companies in the pharmaceutical sector. As a supplier, Luye regularly undergoes audits from its customers. Here, Geiger and his colleagues can point to their MDE solution. "They always think that's quite good, because they are also familiar with these kinds of mobile warehouse solutions," says the warehouse manager. The same applies to inspections by official authorities, who check the documentation, security, and handling of the processed materials.

MDE processes are more secure and flexible, and they save us time while allpwing us to use our warehouse more effeciently.

— Franz Geiger, Warehouse Manager at Luye Pharma

The often 2-day long audits cover all departments and processes at Luye. Documents are checked, and the entire material flow is walked through. "They usually start in the warehouse and, alongside that, they check quality control, production, secondary production, all the way to customer service," explains Geiger.

He notes that since the introduction of the mobile warehouse solution, there have been fewer specific follow-up questions from auditors when they can simply point to the scanners. "We had a case, for example, where we described the scanners to the auditors. We have established a process where we can only scan a code once, and only in a defined sequence, such as during an internal transfer." And all relevant data is captured automatically in the scanned barcode. This makes it traceable for the auditors how processes run in daily warehouse practice and how they are technically secured.

Advantages of the Mobile SAP Warehouse Solution

Employee acceptance is a key topic in any process change. The introduction of MDE technology was received differently among the staff. While younger, smartphone-savvy employees were positive about the new way of working with handhelds, older colleagues were initially hesitant. "But now, you have to say, everyone is glad that we have this system, especially in goods receipt and for internal transfers," judges Geiger.

He illustrates how day-to-day business has been made easier using the example of internal transfers:

- Before the MDE solution was introduced, an employee performing an internal transfer would write down the material number, batch, quantity, and destination bin on a piece of paper. Then, they had to go back to a PC, open the corresponding SAP transaction, and manually enter and post everything. A laborious procedure.

- Today, the documentation is done directly via the handheld device. Each product has a so-called goods receipt (GR) label with a barcode. This is scanned. For example, colleagues can immediately see if there are any remaining quantities. A putaway can then be carried out immediately based on this information.

The result: The MDE solution simplifies the work and also makes it more secure. Expressed in numbers: While the average time required for return transfers was approximately 170 man-days per year, the use of scanners reduced this to 108—a reduction of 36%.

In goods receipt, the advantages of using scanners are also apparent:

- Previously, an employee would take the delivery note and check the goods. Then, they had to go to a PC, open the purchase orders, and post everything. Finally, the SAP labels were printed. The employee had to go get these labels and bring them back to the goods. This was done separately for each material on a pallet and included a walk of up to 50 meters due to the warehouse layout. It was a time-consuming procedure.

- Today, using scanner technology, the employee can process the entire pallet completely on the spot, including mobile label printing directly at the pallet.

The result: Inefficient walking can be largely avoided by using the MDE solution. Expressed in numbers: While the processing time for goods receipts before the scanner was introduced was approximately 116 man-days per year, it is now 68, which corresponds to an effective time saving of 41%.

Future Perspectives and Outlook

For the future, Luye Pharma plans to digitize additional processes and expand the use of its scanner solution. Specifically, integration with the new SAP S/4HANA system and the introduction of an Extended Warehouse Management (EWM) system are on the agenda. Furthermore, other departments, such as primary and secondary packaging, are also set to benefit from the advantages of scanner technology.

A Note on Hardware

At Luye Pharma, a mix of very different mobile devices is in use—depending on the specific area of operation. The same mobile warehouse solution runs on all devices:

- High-performance handhelds in two different models from Zebra

- An explosion-proof handheld

- A rugged tablet for use on forklifts

Conclusion

For Luye Pharma, the introduction of a mobile warehouse solution in intralogistics represents an important step towards digitalization and increased efficiency. The positive effects on workflows are measurable. And indirectly, the MDE technology reduces the effort related to GMP requirements, as it increases process security and reduces sources of error.

Optimize your warehuose easily and budget-friendly with the Ontego subscription model.

.webp)

.webp)