Topics

Simple operation, guided mobile processes, and flexible extensions. These were the requirements that MKN had in 2017 for its scanner solution for SAP warehouse and production logistics. The manufacturer of professional cooking technology relies on the Ontego platform for an SAP app, including an extension for an inventory control center.

What was the trigger that led to MKN's decision a few years ago to replace the paper-based processes in its warehouse? Logistics Manager Thomas Pyschik recalls three major challenges:

- Inventory discrepancies. Inventory accuracy was not assured.

- Process simplification. The goal was for new employees to become productive more quickly.

- Process transparency. Material movements needed to be traceable at all times.

These issues provided sufficient motivation to concretely tackle the switch to a scanner solution in the warehouse.

Learn everything about modern mobile SAP apps in warehouse and production.

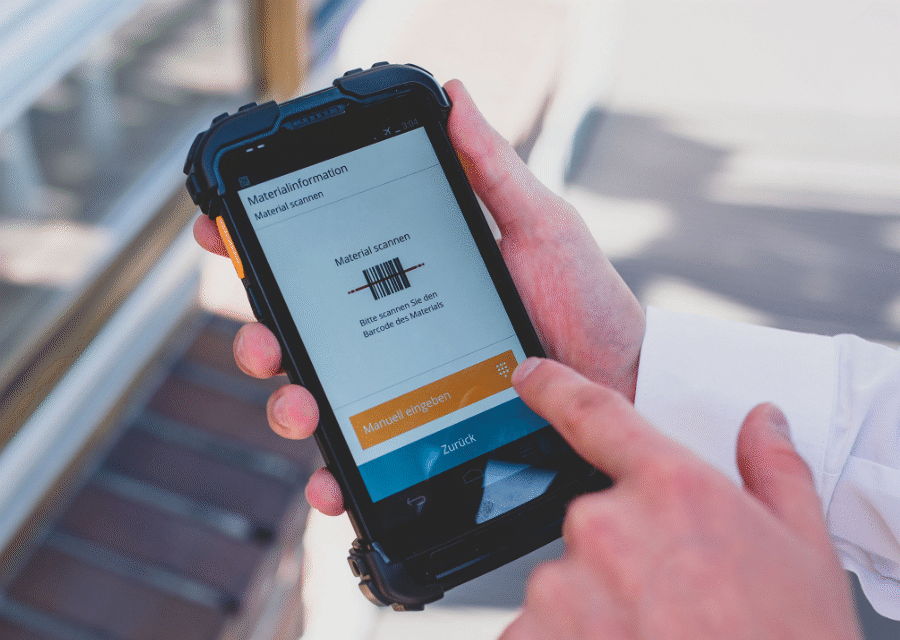

Mobile Hardware – with an SAP Logistics App

In 2017, MKN began a targeted search for a future-oriented mobile solution. At the time of the decision, Windows CE-based handhelds were still the standard mobile hardware in warehouse logistics. Android was only just beginning to replace the then-dominant mobile operating system. In this respect, the decision-makers at MKN played a pioneering role. Furthermore, the following aspects were important:

- Modern Hardware: Ensuring user acceptance of the devices.

- Intuitive Interfaces: A user-friendly design with simple operation, tailored to logistics processes.

- Lean Processes: Seamless integration with SAP and fewer interfaces by eliminating paper documents and the need for PC workstations.

- Guided Workflow: Providing process-relevant prompts directly within the logistics app.

We can reveal this much at this point: The introduction of the mobile SAP solution has paid off for MKN. Pyschik credits two key factors for this success:

- The warehouse employees were brought into the project through their team leaders from the various departments (Goods Receipt, Picking, Shipping, etc.) and were involved by providing feedback.

- The project team implemented KPI-based monitoring, which was made possible by the newfound transparency.

Both of these measures ensured that sources of error in the day-to-day work with the scanner solution were identified early. In addition, the employees provided valuable suggestions on potential areas for optimization.

Process adherence is best achieved when employees feel secure and comfortable operating the devices.

— Thomas Psychik, Logistics Manager at MKN

Step-by-Step MDE Optimization: A Kanban Example

MKN relies heavily on a Kanban-based system. In the initial phase, it repeatedly happened that scanning a Kanban ID would generate a new signal over and over again, without the previous work steps or processes having been completed. "The result was that Kanban containers were being provided in a state that deviated from the target, or were sent to incorrect delivery locations," says Pyschik.

The error was quickly identified in the error log. It was traced back to the predefined workflow in the app. When scanning the Kanban ID, the app would get stuck on the old ID of the control cycle when jumping back, which led to the repeated signal generation. The solution was an adjustment to the app and a time lock between Kanban statuses that was linked to the success confirmation of the previous processes. "It's the little things like that," the logistics manager summarizes.

Guided Putaway and Retrieval with SAP

This systematic approach has also had a positive effect elsewhere in the material flow. "The mobile putaway and retrieval process is heavily controlled, or rather, guided by the app," explains Logistics Manager Pyschik. Unlike the previous method of using fixed bin locations, warehouse staff now have little room for error. Pyschik's team has since switched to chaotic storage so that employees aren't even tempted to pick an item based on suspicion, just because they knew its location from experience.

On the contrary, the app now displays the source bin specified by SAP, and the employee scans it for verification. This ensures that the employee picks the correct material and stages it for production, for example. The only potential source of error remaining today is picking the wrong quantity.

.webp)

The Inventory Control Center

In addition to its mobile processes, MKN uses a browser-based control center to support its continuous inventory counting. The control center includes a separate user administration system to manage access for so-called "count users."

The control center includes the following functions:

- Filtering of inventory documents (MM/WM) created in advance in SAP by planned count date, specific inventory document numbers, or organizational units such as storage locations or warehouse numbers and storage types.

- Display of ad-hoc inventory documents created via the mobile SAP app.

- MM Inventory: Display of individual counts that make up the total counted stock.

- Reconciliation of discrepancies and a display of variances by both quantity and value.

- Uploading of count results to SAP.

- Archive for count documents.

From Pyschik's perspective, the inventory control center is helpful. The tool provides an additional overview of ongoing counts and offers a user-friendly interface compared to the standard SAP screens. In case of discrepancies, a recount can be conveniently organized. The final posting in SAP only occurs after the count results have been approved in the control center.

.webp)

Embedding Product Data with NFC and the Logistics App

A special feature of mobile work at MKN can be found in its production process. Some manufactured kitchen appliances are equipped with an NFC chip. The specific configuration information for a device—such as installed components including serial numbers, the production date, and various other product data—is stored on this NFC tag. The writing process is handled by the mobile SAP solution, which uses the handheld device to write the data to the NFC tag.

How MKN Benefits from the Mobile SAP Solution

"Today's inventory discrepancies are 16 times lower than before the scanner was introduced," Pyschik notes with satisfaction. Since the scanner solution was introduced, discrepancies have continuously decreased year after year. Furthermore, their workflow has largely shifted from paper and manual entries at an SAP GUI to electronic, mobile SAP bookings. On average, well over 2,000 bookings are now processed via the mobile solution each day. That amounts to 40,000 bookings per month, or 500,000 bookings per year.

Benefits at a Glance:

- Low inventory discrepancies

- Short onboarding time for new employees – productive in picking after just one day, compared to several days previously.

- Low error rates

- Scalability of the mobile solution

.webp)

Conclusion

MKN focuses on quality in its products—a standard it also applies to its underlying SAP-managed processes in logistics and production. The introduction of a scanner solution has led to a significant increase in efficiency and transparency throughout the material flow. This is reflected, not least, in low inventory discrepancies. It's not just production that benefits from the error-free supply; in shipping and the after-sales department, MKN's customers also enjoy fast and error-free spare parts provisioning. In addition to the standard MDE processes in logistics, the separate control center application simplifies count management for the logistics leadership. The NFC features provide additional efficiency in production.

Optimize your warehuose easily and budget-friendly with the Ontego subscription model.

.webp)

.webp)