Topics

Tristone Flowtech is a Tier 1 supplier for the global automotive industry. A highly standardized, mobile SAP warehouse solution supports the lean and flexible logistics processes the company uses to meet the demands of its OEM customers.

As part of the Chinese Zhongding Group, the company employs a total of 5,750 people. Production is spread across 12 locations worldwide, 10 of which use the mobile data entry solution for warehouse logistics described here.

Standardizing Mobile SAP Warehouse Processes

Among the managers at the Frankfurt headquarters is Angelo Mattivi, Vice President of IT. He joined Tristone in 2018 and subsequently initiated the project to modernize the company's SAP scanner applications. "At that time, Tristone was using three different warehouse solutions based on Windows Mobile devices," Mattivi recalls.

These legacy solutions provided mobile access to a good 30 processes and functions. The goal was to unify these solutions from a process standpoint and, most importantly, transfer them to a modern, future-proof platform.

They were looking for a solution that met the following requirements:

- Simple to use

- Graphically appealing screens and dialogues

- A modern mobile operating system platform, specifically Android

Another goal for implementing the mobile warehouse solution, as with all digital solutions at Tristone, was to reflect the changing demands of the business environment. The customers—the major car manufacturers—are automating and digitalizing their processes and, in turn, passing these changes on to their suppliers.

On top of that, the business has become more dynamic. Reaction times are shorter, business volume is more volatile, and consequently, the predictability of intralogistics has decreased.

Agile Instead of Waterfall: A Successful MDE Implementation

How did they approach the project? The managers at the Frankfurt headquarters focused on automating all relevant SAP transactions for material handling using a single, unified MDE platform (Ontego).

"It's really about three main processes," explains Nirmal Baskar, IT Operations Lead, "which are goods receipt, production supply, and shipping." Under these main categories, you find sub-processes like putaway, internal transfers and returns, material staging for production, replenishment and picking, or packing.

Learn everything about modern mobile SAP apps in warehouse and production.

VP Mattivi had overall responsibility for the project and followed a clear strategy for planning, customizing, and the rollout. At the beginning of the project, a pilot solution was defined, which was then discussed and adapted in workshops with local managers at the individual plants.

For example, the project managers from Frankfurt flew to Turin for a week to conduct a detailed analysis workshop at the Cirié plant, explains Logistics Manager Katia Galizia. She illustrates the requirements at "her" plant with a few numbers:

- At the Italian plant alone, 1,500-2,000 pallets of incoming goods are received from around 150 suppliers every month.

- 980 different parts are managed in the warehouse.

- Between 2,700 and 3,500 pallets are loaded for shipping and sent to nearly 100 customers each month.

This procedure was replicated from plant to plant, adds Mattivi. A specific gap analysis was carried out at each location.

- Group 1 works with pallets.

- Group 2 uses cage pallets and boxes.

- And plants like Cirié use a combination of both

Successful Project Teams: Central IT and Plant Logistics

The managers at Tristone agree that a crucial aspect of the project's ultimate success was the close and, above all, trust-based collaboration between the central IT department and the local logistics managers.

He is critical of the classic waterfall approach, which is still practiced in numerous IT departments. Requirement specification, programming, and implementation follow a relatively strict sequence.

Mattivi illustrates the issue: The difficult part is that a small group of people, who often barely know each other, define the requirements for a complex scenario at the beginning of the project. These requirements are then handed over to a partner for implementation. And then, high expectations are placed on the rollout.

This is all under the condition that there are no changes whatsoever along the way. That is hardly compatible with reality—and often leads to disappointed expectations.

Therefore, the VP of IT advocates for a more agile approach, one that allows the gap between the pilot solution and the practical reality to shrink with each rollout. That is important. The gap should get smaller step-by-step. The expectation is not that the final solution will be designed in the initial requirements workshop. This procedure is also ultimately cheaper, as it eliminates costly rework.

The main goal was to standardize all of our mobile SAP logistics processes. And we achieved that goal.

— Angelo Mattivi, VP of IT at Tristone Flowtech

For all the standardization, there are differences between the plants in their work methods and process sequences, says Baskar. "Some plants pack finished parts on pallets, some in boxes, and still others use both pallets and boxes." These specific details are also reflected in the picking process.

And ultimately, the customization of the warehouse app was tailored to this. An agile implementation was carried out together with the project team from commsult, the manufacturer of the Ontego platform for mobile SAP processes. Some of the requirements were implemented in the mobile warehouse solution, while others were handled directly in the SAP backend.

Paperless: SAP Picking Orders

Before the introduction of the standardized scanning solution, Tristone had picking lists that could be up to 20 pages long, says Nirmal Baskar. The implementation of the mobile warehouse solution has drastically reduced paper consumption. Katia Galizia adds: The warehouse workers are faster at picking and more accurate, thanks to the mandatory scanning of handling units.

This is particularly noticeable at Tristone's Cirié plant, because there are very different customer requirements, such as standard containers alongside small containers specifically for Ferrari. These specific requirements are reflected in the mobile solution

Simpler: WM Transfers

Before the standardization, there were paper-based processes that are now completely digital—for example, internal transfers. In the case of production supply, an employee selects a requested material on the mobile device, scans it, and enters the quantity removed. In the background, Ontego creates the transfer requirement, which then triggers the creation of a transfer order. The physical movement of the material then takes place based on this order. At the destination, the TO is confirmed on the mobile device. This makes the entire transfer process simpler and easier to control.

Thanks to the scanner solution, we are faster in shipping, and the loading process is more secure thanks to verification scans.

— Katia Galizia, Logistic Manager at Tristone Flowtech

New: Loading Control with Handling Units

Here's another example: During loading, there are potential sources of error that automotive OEMs push their suppliers to eliminate. Baskar explains: "Let's imagine a shipment contains 50 pallets. Either I don't load all 50 pallets, but only 48, and forget the last two because there are hundreds of pallets in the shipping lane. Or I load the wrong pallet."

With the Ontego app, the delivery note is scanned, and the warehouse employee is shown a list of all pallets that need to be loaded. Each pallet, or handling unit, is scanned as soon as it is on the truck. The corresponding HU is then marked in the app, allowing the employee to see at a glance which pallets have not yet been loaded. If a wrong pallet is scanned, the employee receives an error message in the app stating that this pallet does not belong to this shipment.

A User-Friendly SAP Warehouse Solution

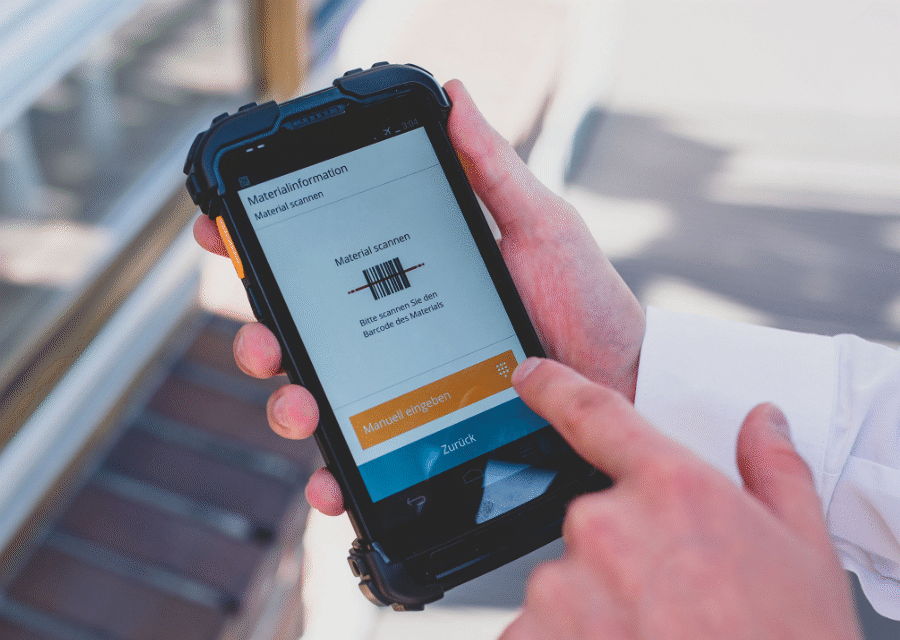

Last but not least, one of the biggest differences between the previous scanner solutions and Ontego is user-friendliness. Today, warehouse staff have a single, central logistics app on their handhelds to access all the SAP functions they need.

The user interface is modeled on the consumer apps that employees use every day in their personal lives, for example, using simple and universally understood icons. The nested menus that were common in the past are gone. Today, employees are guided through a process step-by-step, one screen at a time.

According to the Tristone managers, all of this has increased user acceptance. Baskar adds that the mobile solution is largely the same at all locations and is used in the appropriate language for each site.

The standardization makes employee training easier, as the mobile warehouse solution is largely self-explanatory.

— Nirmal Baskar, Team Lead IT Operation at Tristone Flowtech

Conclusion

From Tristone's perspective, standardizing the various scanning solutions was a success. Time, budget, and user satisfaction were the key factors for evaluating the project. In addition to the direct posting of material movements in SAP, the mobile solution also enables supplementary functions like label printing and mobile handling unit management. With this, the logistics team has gained a central mobile layer to document the material flow from goods receipt to shipment in real-time.